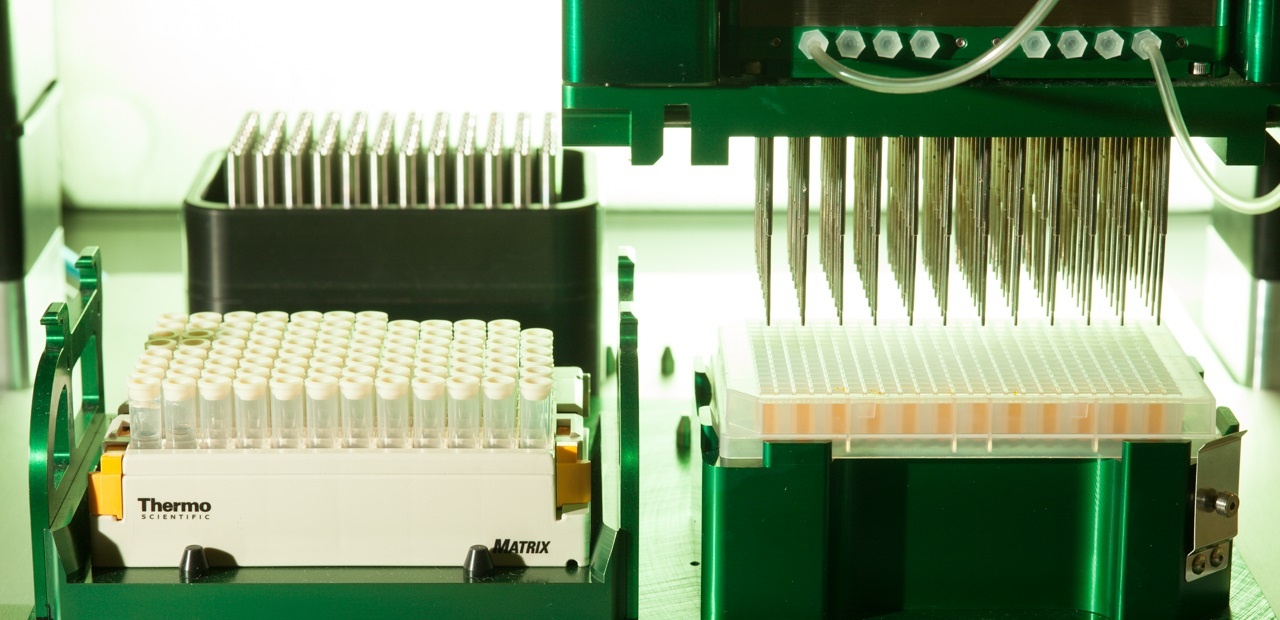

Rest easy, your wonderful new liquid handling robot will:

- Perform its defined pipetting processes extremely well with great accuracy

- Enable much higher throughputs with minimal errors

- Run unattended, freeing up scientists to get on with more important tasks, like science….

However, you need to get the best out of it in your workplace. So:

- How do you make it productive quickly?

- How do you incorporate its results into your data workflows, to gain painless and error free inventory updates?

- How are you going to process and track your samples as they pass through it?

Where Do I Start?

You know you want a plate of samples in a specific format, and that your liquid handler can do this quickly – but what is the process? What are all the steps needed to achieve the finished result?

You need to be able to:

- Locate your samples:

- identify the compounds from an inventory search or request them remotely

- track down their location and retrieve them from storage

- track down the reagents and labware to be used in your plate creation and assay - Give the liquid handler a protocol to create the desired output:

- instruct the liquid handler where the samples, labware and reagents will be located on its bed or stacks

- tell the liquid handler the required format and layout for results

- write a script of actions for the liquid handler to perform, including dilutions and picking from multiple input sources

- check there are sufficient quantities of sample and reagents available, allowing for dead volume and reservations - Load the liquid handler:

- clear the bed of samples and labware from previous runs

- place labware

- place sample and regents and empty labware in the correct locations and correct quantities

- check sufficient consumables or reference substances are available - Run the liquid handler protocol

- Check the results:

- report any errors, and finish the workflow if it has paused or errored

- update your inventory with new sample locations, well numbers, daughter plates, volume levels - Deliver the new plates created for testing and analysis

- Make sure the plate data is available for your analysis

This sounds complicated – and it is! Even if you just run a simple plate-replication protocol continually, your liquid handler is not the only part of your workflow. You still need to be able to track your samples and how many plate copies you’ve made, whether the source plate is close to depletion, if it is the last one you’ve got, and who the output plates have been given to.

Liquid handling robots solve the problem of moving precise quantities of liquid efficiently and reliably, but they are not set up to:

- Carry information about the contents to be processed – they do not handle sample metadata, or information about what has happened to your samples outside that robot

- Automatically load themselves – they need to be correctly prepared to run, with the necessary samples and labware tracked down and placed ready

- Fit their results reporting into your wider workflow without integration

Integration Strategies for Digitising your Lab - Part 1: Liquid Handling

This white paper looks at the different approaches to integration and questions to consider when integrating liquid handling equipment in your lab.

Read the white paper

How Do I Integrate It With My Lab?

To manage your lab workflows efficiently, or provide an audit trail, you need to be able to connect your new liquid handler to your sample data and to other processes. This is usually tackled by:

- Constructing a spreadsheet – but this is often complex, it must be laboriously updated manually and is prone to errors

- Asking your IT department to provide a macro or bespoke software – but this must be created individually for each new piece of lab automation and be supported for the life of the automation.

- Using available sample management software or a LIMS system which can interface to all your lab automation (Learn more about laboratory sample management here.)

Integrating your liquid handler into your workflow can be hugely simplified with good lab management software like Titian’s Mosaic.

Mosaic Sample Management software integrates with a wide range of automation and provides:

- Interfaces to manual and automated stores so it can create pick jobs for the operators to retrieve the required samples

- Tracking, reserving and restricting use of samples, reagents and labware

- Error-free creation of pipetting protocols for liquid handlers

- Interface to allow operators to guide the liquid handler on where items are placed

- Advanced tip usage/tracking

- Automated data processing and live inventory updates, to avoid delays

- A full audit trail, which is 21 CFR Part 11 compliant

In-house spreadsheets are often used to fulfil some of these functions but have drawbacks:

- Errors with traceability – it is, unfortunately, too easy to use a source plate that hasn’t had its inventory updated by mistake, with the error only recognised during assay analysis and after wasting precious assay reagents.

- Macro errors within the spreadsheet or across spreadsheets

- Access to information – for instance, when identifying hits, it can be difficult to dig back to find out exactly what combination was in the hit well and where it came from

Tackling Larger Automation Systems

Larger automation platforms – such as those from Azenta, Tecan, Hamilton, HighRes Biosolutions or Beckman Coulter – can run overnight and handle much higher throughputs. This places increased demands on the systems in place to integrate them with your processes. Can spreadsheets manage that?

Such automation platforms manage their internal workflows extremely well, but they are not designed to manage the ancillary workflows around them to complete the drug discovery cycle. Thus each request from a scientist has to be treated as a separate job to be completed. From an operator point of view, what the platforms present is a series of dull but necessary checks and validations to ensure the order and the platform are set up correctly in order to run. With a lab management system such as Mosaic, however, a scientist creates an order and Mosaic automatically writes the scripts, checks restrictions and volumes and can even bundle similar jobs, so that when the automation platform receives the order, it is optimised, validated and ready to go.

The challenge for today's lab is to connect their automation platforms to the screening cycle so that the essential work done by these systems can be viewed and managed as part of the whole. Titian Mosaic software works to present the big picture of early drug discovery screening processes by providing integrations both up and downstream of the niche filled by automation.

Next steps:

Our white paper, Integration Strategies for Digitising your Lab - Part 1: Liquid Handling, looks at the different approaches to integration and questions to consider when integrating liquid handling equipment in your lab.

Our white paper, Integration Strategies for Digitising your Lab - Part 1: Liquid Handling, looks at the different approaches to integration and questions to consider when integrating liquid handling equipment in your lab.

Want to know more?

There is more information on managing lab automation available from these links:

- Titian's Integrations web page

- Tecan's blog 'Are we nearly there yet?'

- Titian's application notes, available from our Resources web page

OR consider talking to one of our Titian experts

– There is a better way to manage your liquid handler!