With visions of the kitchen scales and weighing out 'well-behaved' recipe ingredients, people tend to think of weighing as a simple straightforward process. However, the weighing of biotechnology samples can be anything but simple. After addressing environmental factors to ensure an analytical balance will weigh accurately, there are also process factors to consider.

When everything is going smoothly, the process of weighing out lab samples can be well-defined and managed, but it can range from a few samples a day in a small biotechnology company to thousands of samples in a dedicated Contract Research Organisation (CRO), which creates challenges of its own.

Even a 'simple' weighing process has a range of decisions that need to be made and questions to be answered. For example:

- What vial type does this particular order require?

- Should I check-weigh the vial?

- Does it need labelling?

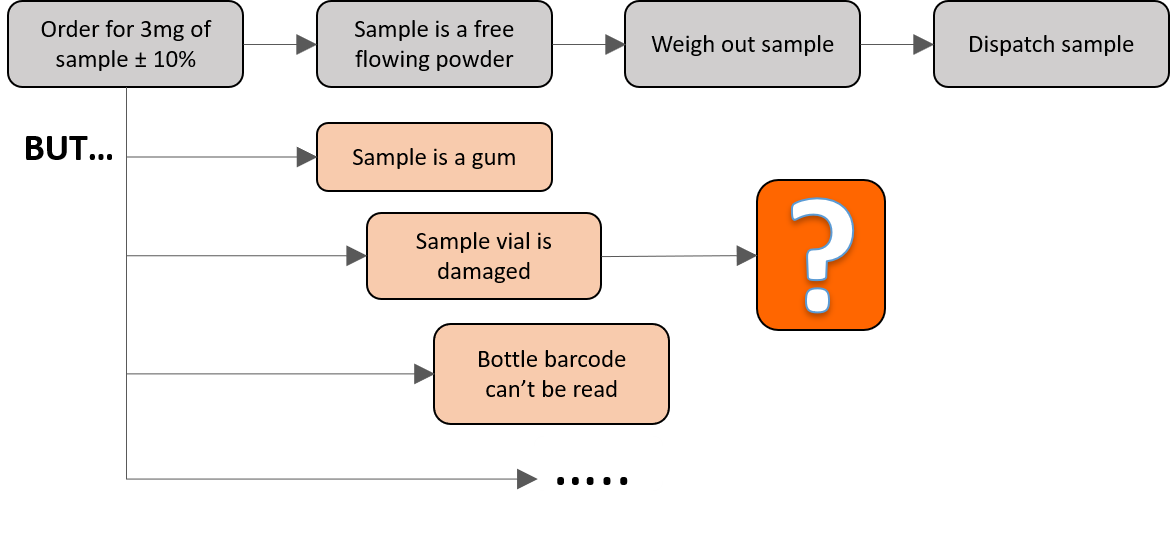

These quickly become complicated if something unexpected happens – the powder you’re expecting to weigh out is a gum, the sample bottle is cracked, or the bottle barcode can’t be read. What do you do then?

The complications that could arise – and their solutions – introduce a significant number of variables that jeopardise the consistency of your process, the accuracy of your inventory and thus the integrity of your data.

The difficulty is to manage these many possible cases in a way that is consistent but is flexible enough to cope. This is an area where dedicated sample management or LIMS software should support you by providing a streamlined weighing process that provides operator guidance, while ensuring your inventory is kept up to date and recording a full audit trail of operations. One example of such software is Titian’s Mosaic, which has a dedicated Weighing application.

By looking at some examples we can illustrate the sort of scenarios and issues that might arise during weighing. A simple request to weigh out 3 mg of a sample could give rise to one or more of the following problems. These are all solvable, but to have an efficient weighing process that avoids delays these need to be solved quickly and consistently every time.

What value range is acceptable, and what is the final mass transferred?

In practice it is extremely difficult to weigh out exactly 3.00 mg, which means an acceptable range needs to be calculated where the amount weighed is neither too low to be able to complete the required process, nor so high as to waste compound.

This calculation is open to human error, takes time and requires a knowledge of what else is happening to the sample. Ideally, it would be done automatically by your sample management software, which would also accurately capture the actual mass transferred without the need for manual data entry, and update your inventory.

What type of vial do I need to weigh into, and does it need a label?

Most weighing processes are a single dispense from source to destination, but the next steps affect what destination container is needed. For instance:

- Will the sample be solubilised?

- Will it be sent to an internal scientist?

- Or shipped to an external collaborator?

Each of these options potentially requires a different vial type, rack type and/or label information.

Sample management or LIMS software should manage this process for you to ensure the right containers are used each time and, if needed, print out labels with the necessary information.

How much sample do I actually have?

It might seem unusual to question your carefully constructed records, but there are a number of ways that their accuracy might be affected:

- The first and most significant is manual data entry which, inevitably, brings human error with it. Ideally, your sample management solution should integrate with your analytical balances to automatically record weighed amounts and update your inventory immediately.

- Another way to reduce errors is to send out pre-tared vials to your chemists or suppliers. When you receive these back, your sample management solution should prompt operators to check-weigh the vials against your records so your inventory can be updated if the expected and actual values differ.

- Even using sample management software with an integrated balance, anti-static bars and each dispense accurately recorded, small amounts of material will still be lost. Over time this will affect the accuracy of your stock. To account for this, it is useful to check-weigh vials when a predetermined number of dispenses have been performed and record any adjustments.

The source vial is damaged and needs replacing

When you come to dispense a sample, you may discover that the source vial is damaged, or the barcode can’t be scanned. When replacing a container, you also replace the container ID, but it is vital not to lose all the data associated with the old container. Manually transferring this is time consuming and a potential source of error. Ideally, your sample management system should allow you to replace or update containers and transfer all work linked to the damaged vial to the new container.

The sample is not a free-flowing powder but is a gum

Having received the samples to weigh, perhaps one or more of them are gums. Whilst it might be possible to transfer a sample of the gum, this is wasteful as a significant amount is likely to stay stuck to the spatula during the transfer. It might be better to dissolve the gum first, but this is a complex process requiring the sample to be sent to a liquid handler for solubilisation and transfer. Transferring a sample to a different process presents tracking challenges as well as interrupting the workflow. For instance:

- Will your liquid handling process perform the correct calculations to get the required amount of sample?

- Can you put weighing this sample on hold while it is solubilised, and continue with others?

Titian’s Mosaic software has seamless liquid handler integration, which is particularly useful in cases like this. It allows you to transfer the work away from the Weighing application and automatically handles the solubilisation and transfer volume calculations for you. When complete, the sample(s) are dried down and you have the option of performing a check-weigh to complete the process.

This sample has multiple dispenses requested

You are weighing out a sample and you notice that there are two or more weighing requests for it. If the request that you are processing has two dispenses, it is straightforward to continue with the second dispense.

However, it is more likely the second dispense is for another recipient. How should that be managed, and the choices tracked?

- One option is to return the sample to store, ready to be picked again for the second request – but this is inefficient.

- You could hold the sample in a new rack ready to process, but you need a means of notifying your inventory that you are holding the sample temporarily so it does not become lost.

- A third option is to perform the second dispense immediately but, again, you need to indicate that the dispense has been done and is waiting with you for the remainder of that sample order.

Because weighing is often outsourced, either to a CRO or an internal contractor, you may also wish to manage these options to indicate one preferred process. A good sample management software will allow you to manage user permissions to control which operations are available.

Tracking an ad hoc dispense outside a workflow

Process control is essential for good management, but there are times when you might need to dispense some sample that is not requested by the usual workflow order. For example, you may need to create a new stock bottle for an automated store from a larger manual store bottle. Your sample management system needs to allow for such ad hoc cases.

Not enough sample

What do you do if the sample weight for the sample vial shows there is not enough for the required dispense? There are several ways this could be approached:

- You can simply abandon the dispense but you need to be able to record the failure as well as the reason for it, so that the requesting scientist can be updated and restocking initiated.

- If you doubt the accuracy of the recorded weight, and the sample has a tare weight, then you could perform a check-weigh to determine the sample weight more accurately. If the check-weigh shows the sample quantity is enough, the dispense can go ahead.

- If there is enough sample to satisfy the request, but not enough to dispense from the vial, you could choose to give out the whole source vial. Again, you need to be able to update the inventory that this has been done.

You need greater control over who can do what

What if the source vial contains insufficient sample so you want to override the minimum amount that can be dispensed?

If you work closely with your customers you may know they are able to accept a smaller amount, so you could have the operator override the ordered amount and proceed. However, if the weighing is being done for you by a CRO or an internal contractor, you may want to approve this action before it is carried out.

Different levels of permissions would allow you to manage authorisations as well as controlling what options are available.

Managing the weighing process' possibilities

In summary, the examples described here help to ensure the reliability and accuracy of the weighing process and your inventory, whether you weigh two or 200 samples in a day. These examples also demonstrate the complexity that arises from the wide range of process possibilities.

A good sample management system, such as Titian’s Mosaic software, addresses all these possibilities, providing guidance for your operators and allowing you to manage the weighing process seamlessly.

To make a complex process like this feel easy, your software should automatically perform as much of the processing as possible in the background, with information delivered to operators as they need it, the inventory updated in real time, and all steps recorded in your audit trail.

Download our Weighing app note to see how this application supports and manages an efficient workflow.

More about Mosaic software:

Request a free trial of Mosaic sample management software.

View our Resource Centre for videos, application notes and white papers.

In any case, consider talking to one of our Titian experts – there is a better way to manage your samples!