To find potential drugs faster and more effectively, the pharmaceutical industry test mixtures by ‘pooling’ tens to hundreds of compounds per assayed well. Biotechnology companies also study mixtures of samples with varying concentrations per well. The method relies on extremely accurate sample tracking to ensure the integrity of the resultant data.

Pooling substances for screening has significant benefits, including:

- Enabling the study of synergistic or antagonistic effects of samples in combination

- Substantially reducing the quantities of samples, reagents and labware required per assay

- Improving error-tolerance by reducing false negatives and positives [1].

Combination therapies rely on testing mixtures to make sure that the combined compounds don't interact negatively or have undesirable effects. Alternatively, the genetic complexity of many diseases means that focusing on a single target may not produce a sustained effect because of pathway redundancy and/or resistance mechanisms. To produce effective clinical responses, especially in oncology research, companies are regularly performing combination screens focussed on multi-targeted drugs or drug combinations.

However, without accurate sample tracking, assay results cannot be reliably and properly analysed, nor can assays be repeated or scaled up.

How do you track compound mixtures?

The main challenge for accurately tracking mixtures of samples is the sheer number and variety of variables to be traced. This is because:

- Mixtures can comprise hundreds of substances, each with its own properties

- Mixtures may combine multiple substance types, for instance when exploring small molecule and antibody interactions, and need to record different properties for each substance

- Mixtures can include multiple solvents, each with its own data

- The proportions and concentrations of each component in a mixture vary from well to well

- Mixtures can be added to other mixtures

- Plates or vials of sample mixtures will need to be replicated or stored for use in subsequent assays

The number of variables to be tracked are outside the capacity of spreadsheets and not covered by most inventory or LIMS systems. So what other options are there?

An industry-standard software solution

Titian’s Mosaic, the industry standard software for sample tracking, has specific capabilities for managing mixtures starting from the assay request, through creation on automated liquid handling platforms, to subsequent data exchange with downstream analysis systems.

This enables researchers to easily:

- Track and view the components and parentage of the mixtures they are handling any time

- Automatically allocate samples to pools by selectable business rules, for instance by molecular weight

- Track the despatch and shipping of sample mixtures

- Automatically transfer of mixture data to external analysis systems

Mosaic software guides the user from the moment mixtures are created, through all transfers, to when the sample mixture is shipped. Mosaic also keeps an audit trail of the whole life cycle of the sample mixture.

Users can easily register mixtures in Mosaic individually or using its bulk file import.

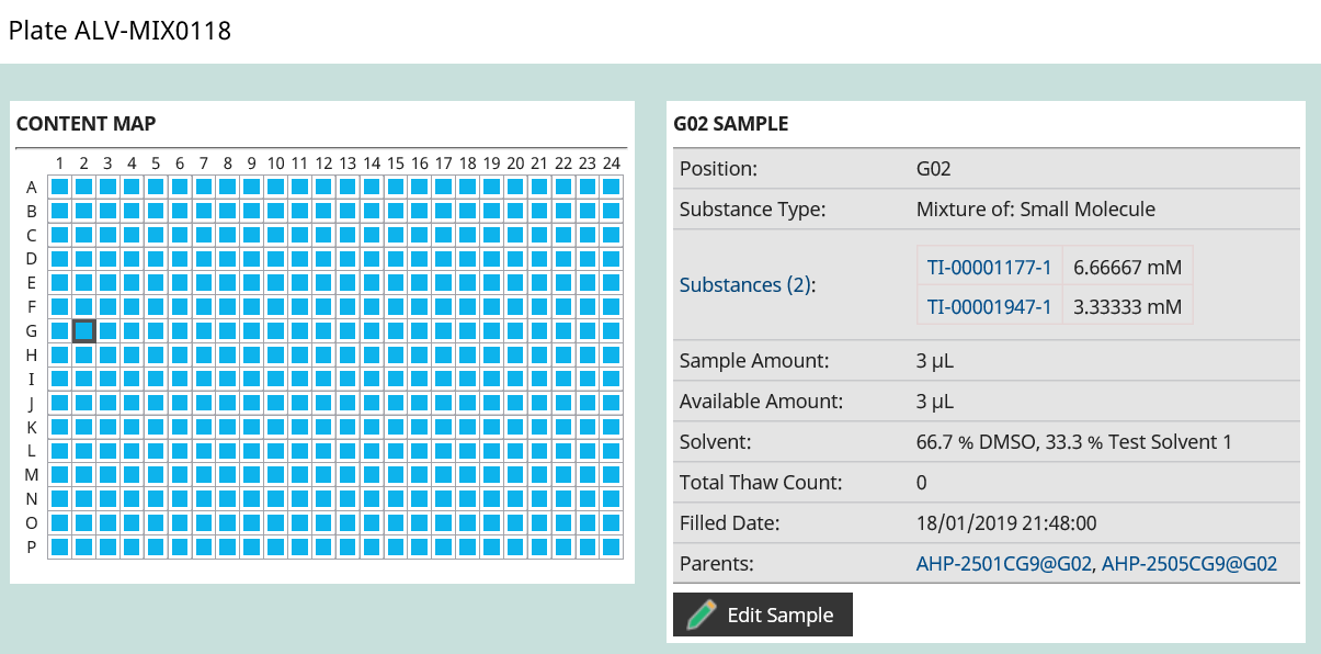

All the details about each mixture are conveniently displayed on the user interface, including identification and concentration of each mixture component.

In the example screenshot below, the selected well (G02) contains two different substances at different concentrations (listed in Substances) in a total volume of 3 µL of a mixture of solvents (listed in Solvent). It also indicates the specific containers that were used as sources for the selected mixture (listed in Parents).

Mosaic can track mixtures:

- With large numbers of substance constituents, each with their specific substance type, concentration, concentration unit (e.g. mixture of biological substance and small molecule)

- With multiple solvent constituents

Users can also record and track transfers from multiple sources into one output container (to create a mixture), or transfers of mixtures from one plate to another plate(s) (replication), or from a vial to another vial(s) (aliquotting).

Mosaic software also tracks mixtures as they are stored or retrieved from manual stores or in automated stores integrated with Mosaic. Researchers can place orders for whole samples or aliquots. The operator is then guided by Mosaic through the retrieval of the samples from the store and processing.

Because pooling requires the precise transfer of very small amounts (often nanolitre quantities) of several substances into one well without contamination, acoustic dispensing is often used because its single transducer head is highly accurate and non contact. Mosaic software integrates closely with acoustic dispensers to offer an easy way to specify, create and track pooled assay plates.

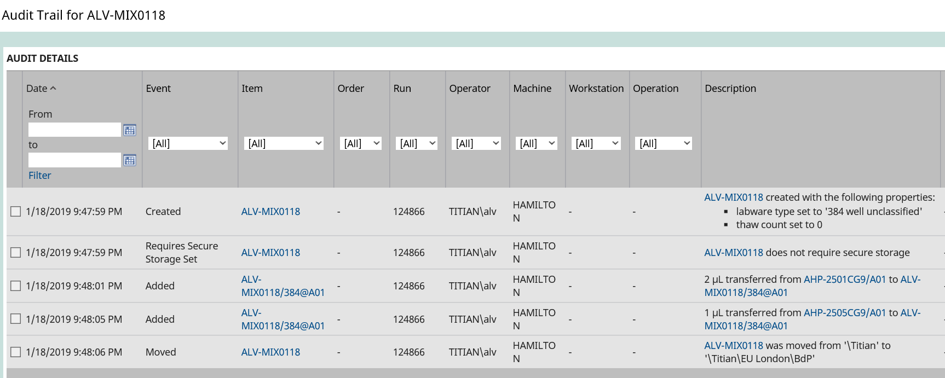

Mosaic logs all sample transfers and moves as labware is sorted or scanned on various devices. Every operation is recorded in Mosaic’s detailed 21 CFR Part 11 compliant audit trail. For analysis, a clear plate map of the delivered labware is provided via REST API or despatch note attachment.

Finally, Mosaic can also track the dispatch and shipping of mixtures to other sites. The data associated with the mixtures can also be transferred to external systems, for example: IDBS ActivityBase or Genedata Screener.

Making combination screening easy

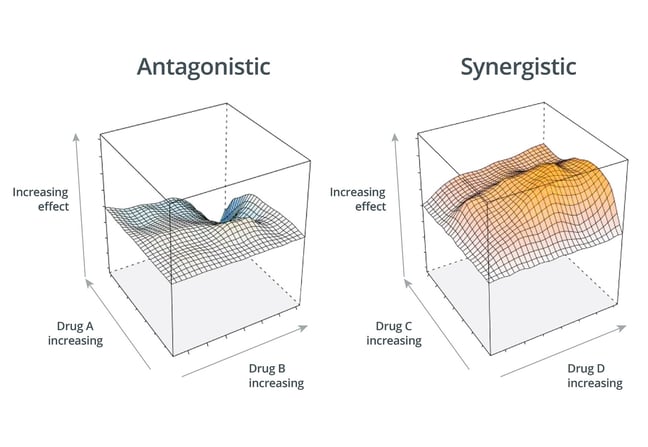

The purpose of combination screening is to investigate whether combining two or more substances will enhance or inhibit their biological effects. One way to test this is to run a cross-titration with one compound arrayed across the plate, and another down the plate, looking for synergistic or antagonistic effects.

One integrated and effective solution for combination screening and analysis combines Mosaic software with Beckman Coulter’s Echo (previously Labcyte) and Genedata Screener. These three products work very tightly together so that:

- The design of screen is created in the Echo Combination Screen application[2]

- The substances to test are allocated to layers of the screen and the Echo protocol created in Mosaic, which also manages tracking the substances from storage through the screen

- The resulting data is fed directly into Genedata Screener for analysis[3]

Using these three market-leading products together:

- Provides a clear picture of results

- Automates the rapid and accurate creation of combination screens

- Ensures every component and quantity is automatically tracked and traceable in a 21 CFR Part 11 compliant audit trail

These features contribute to making Mosaic sample management software the most convenient and powerful tool for tracking inventories of any type of samples, including mixtures. With its reliable and comprehensive audit trail, it offers confidence in all the samples that are being handled and tested.

Case Study

Ribometrix: Improving Management of a

Complex Sample Inventory

Find out how Ribometrix and Titian work together to solve complex sample management challenges and help Ribometrix with their new drug-discovery paradigm.

References

[1] Pooling in high throughput drug screening (Curr Opin Drug Discov Devel, May 2009)

[2] Web page: Echo Combination Screen

[3] Web page: Genedata Screener for combination screening