It’s not just samples that get transferred from one piece of labware to another – the sample containers also move from place to place and their positions may need to be adjusted or consolidated.

By using Mosaic software to control your AltemisLab scanner, you can easily check and verify the physical positions of scanned tubes with the positions recorded in your inventory in Mosaic.

Learn more about the integration specs by downloading the application notes.

Mosaic Sample Management software provides workflow management and inventory tracking to enable a seamless, error-free, sample supply chain and comprehensive audit trail.

Mosaic’s modular approach makes it easy to start small and upgrade or extend the software’s functionality whenever needed. It also integrates with a huge variety of other automation and software to bring these into your laboratory workflow and provide a 21 CFR Part 11 compliant audit trail for the entire sample life cycle.

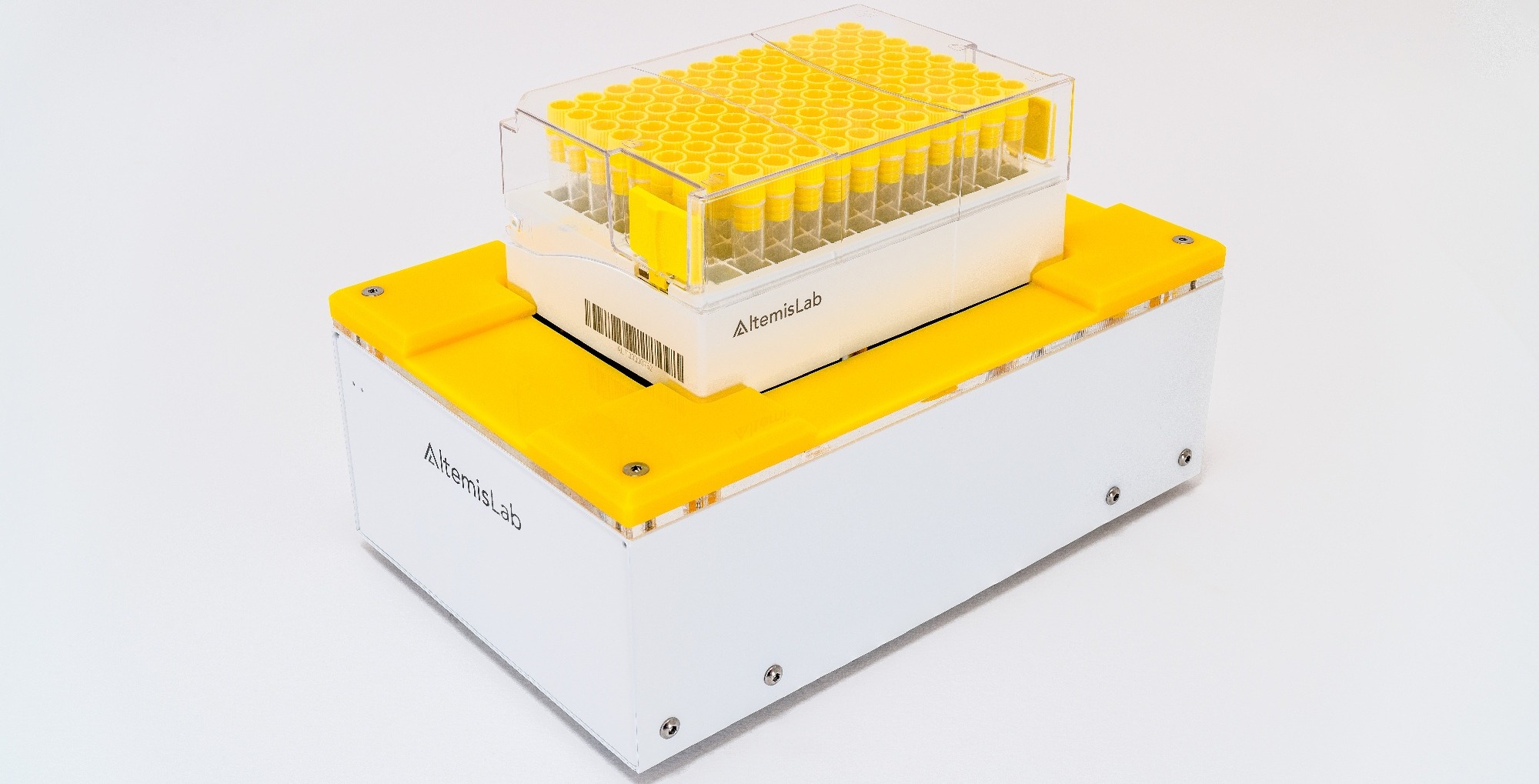

The founders of AltemisLab have been working with 2D barcoded tubes since 2000, when this technology was first used by pharmaceutical companies for compound storage.

Using their knowledge and experience they have set out to perfect 2D tube design and are proud to introduce the AlteTube range of sample storage tubes.

AltemisLab 2D barcoded tubes, barcode readers, de-capping, capping and handling equipment, labelling technology, and lab tools symbolise a new era of efficiency. With AltemisLab you can rest assured that compliance, quality control and manufacturing excellence are unrivalled.